Can I use less material to design the main landing gear while satisfying all the requirements? …

Design

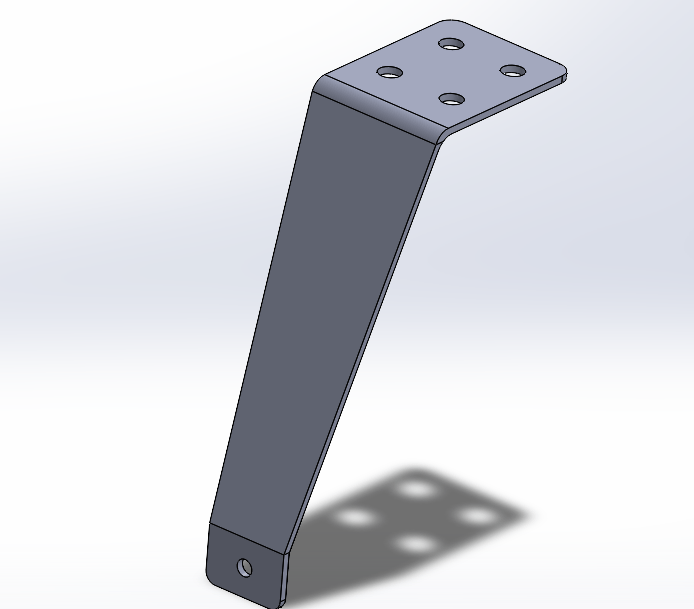

This is another interesting design I did for my engineering design team UTAT (University of Toronto Aerospace Team) SAE competition which we have already joined at least 3 times changed its rule totally in 2025. Planes we built in the past are huge fixed-wing planes compared to the plane for the 2025 competition because of the rule change.

According to the rule’s change, STOVL (short take-off and vertical landing aircraft) for 2025’s competition, and the wingspan of the plane was set to be 1m which is considered to be small. Therefore, the landing gear is considered to be smaller than last year’s.

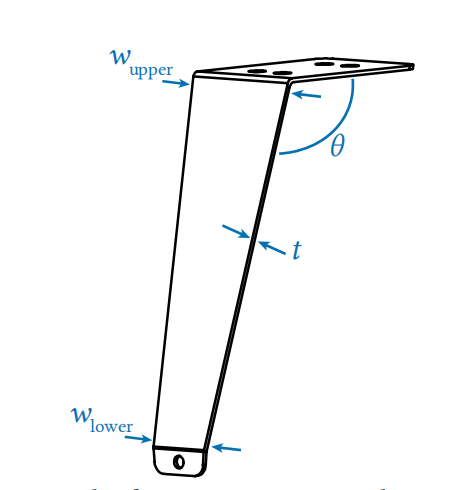

The landing gear has some key dimensions:

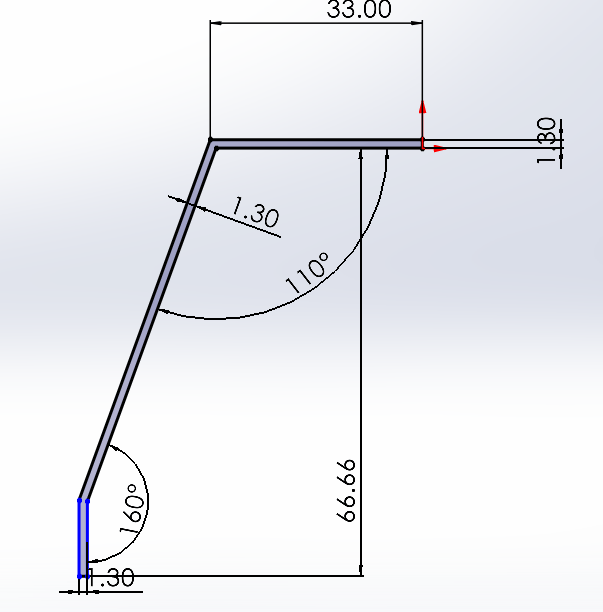

These dimensions were treated as the input variables which can be changed in the Matlab for the later sizing process. The height of the landing gear is constant which was derived from and based on the conceptual design dimensions.

The design of the landing gear is an iteration. The landing gear sizing was done first to determine the landing gear geometry dimensions and this was done in Matlab based on the solid mechanics analysis. Then with the given dimensions, the landing gear geometry was created in SolidWorks.

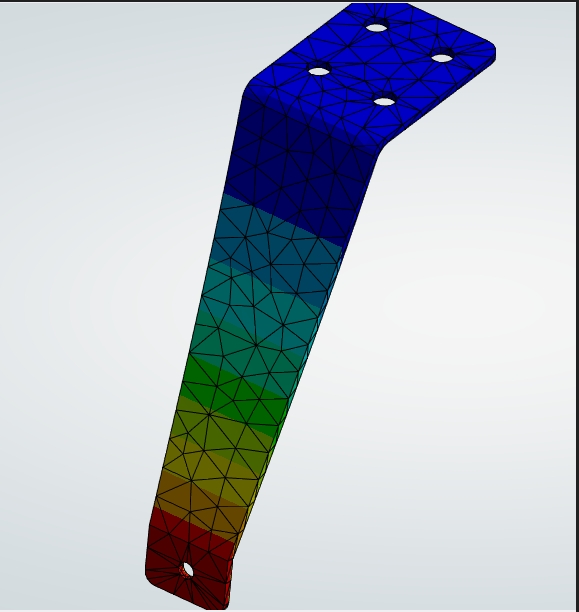

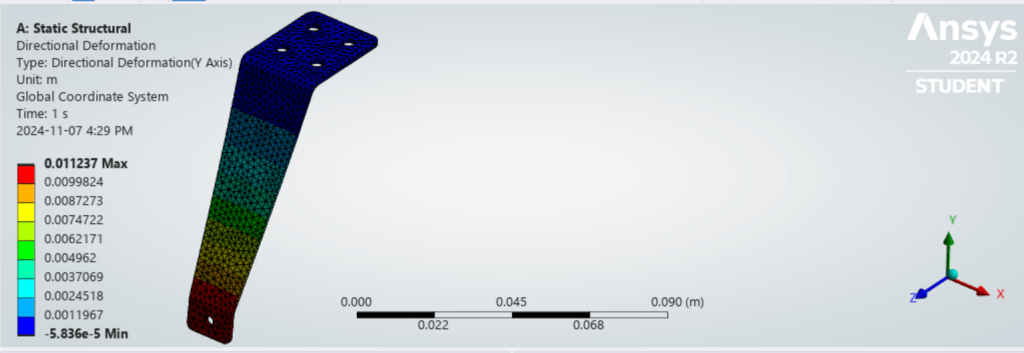

Next, the geometry was imported into ANSYS to simulate the vertical deflection under the assumed load/landing conditions. The composite material of wet layup woven carbon fiber was selected as it was the one used for making those landing gears.

A mesh convergence study was done too to make sure the good mesh quality could give accurate stable results. Then by changing the size of the mesh, the vertical deflection result became stable which proved the quality of the mesh.

The result was very small, and the reason could be the model of the analysis was not as accurate as what it actually was in reality. However, the results were expected to be small which was also shown to be correct in the physical tests. In addition, all the landing gears were made by hand. Therefore, it may also cause the difference between the FEA and real results.

Build

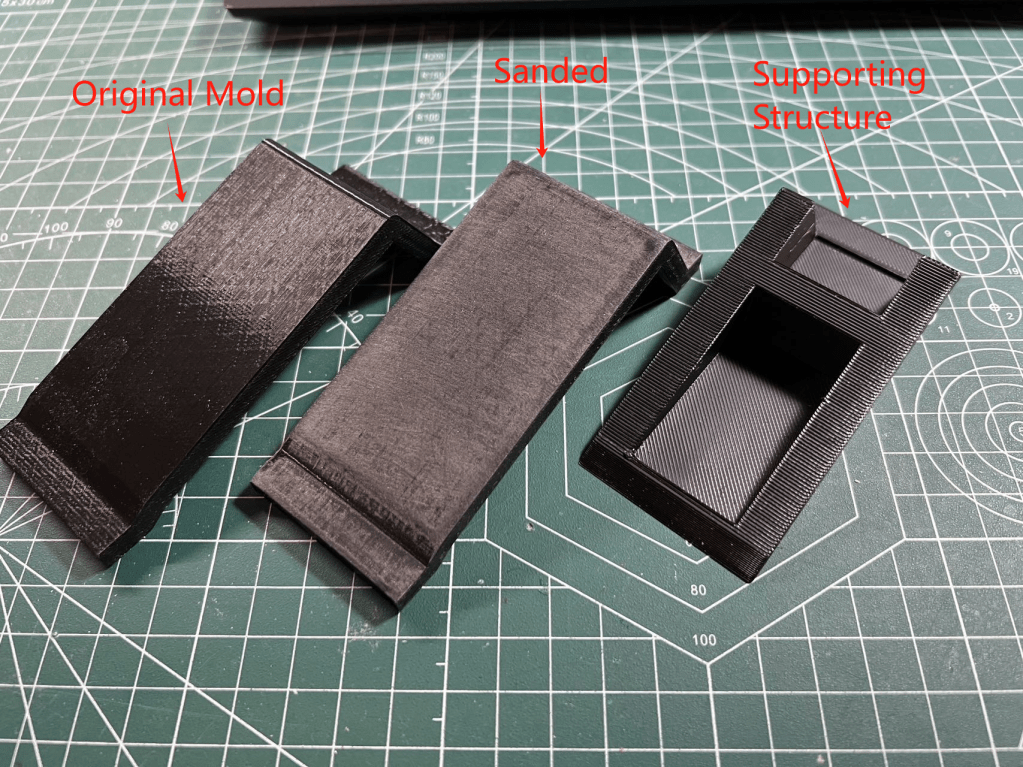

The landing gear was made using woven carbon fibers and epoxy as matrix stacking on each other layer by layer (Like Oreo). The whole wet layup was done on a 3D-printed PETG mold.

The whole layup and the mold were then vacuumed till the landing gear turned into solid. This process is necessary since it can help remove the extra epoxy making the landing gear have more evenly distributed epoxy layers (although it was still a little bit bumpy as a result) and guaranteeing all carbon fiber layers are close to each other to have high strength and stiffness landing gear structure.